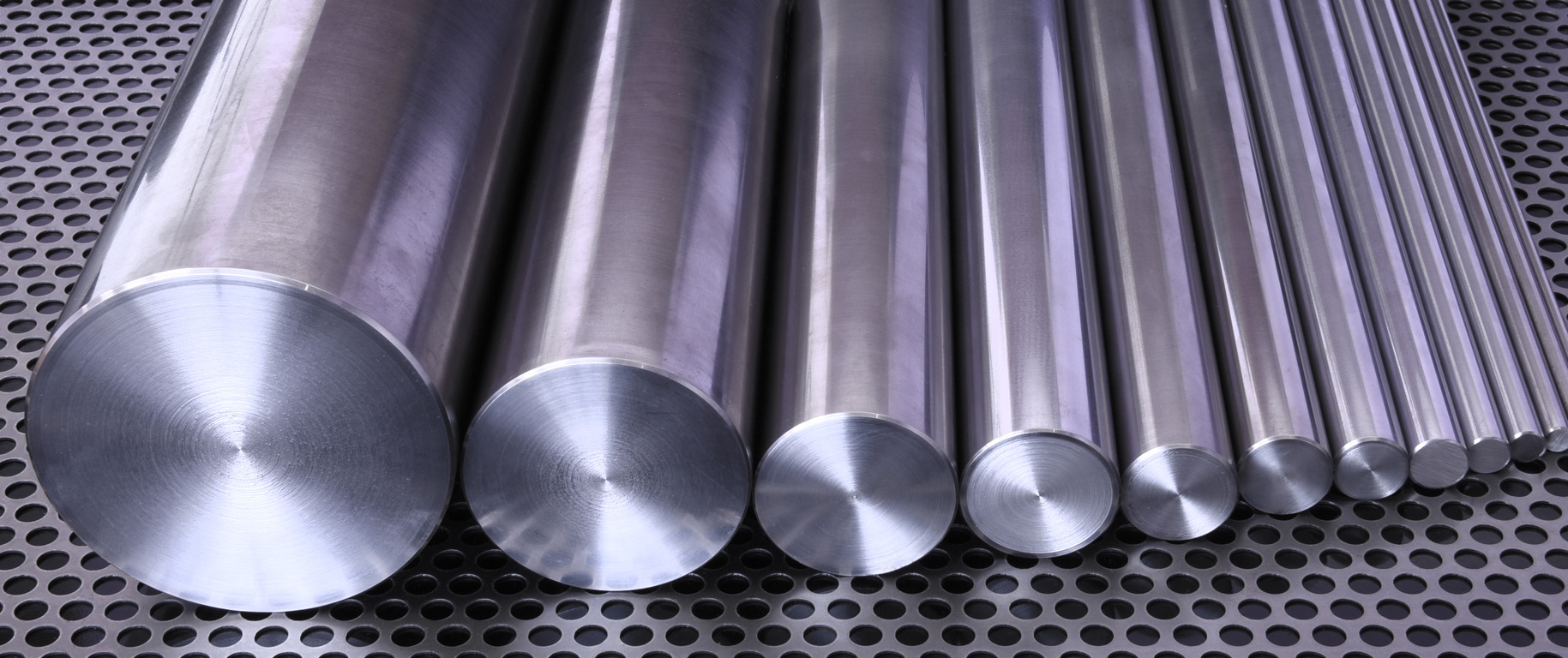

Headland has a wide range of hardened ground shafts in stock, both in solid and hollow, carbon steel, stainless, and hard-chrome plated, and in a wide variety of metric and imperial diameters.

There are various factors you should consider when choosing the shafts you require for your application

Material Integrity:

Hardened ground shafts, also called linear shafts or precision shafts, are steel shafts where the outer layer has been induction hardened. The ground finish, hardened exterior and “soft” core mean the shafts are perfect for linear applications demanding the highest levels of material cleanliness, surface topography, uniform surface hardening in radial and axial directions, tight tolerances in diameter, taper and roundness, surface finish and straightness. This ensures optimum performance at minimal maintenance and long life.

At Headland, we only source material from a key number of world-class material suppliers, which ensures the metallurgical integrity of the products we supply, combined with generous stock availability to be able to respond to our customers’ production needs.

Material Selection:

Diameters & Tolerances:

At Headland, we understand the vast variety of applications for the use of linear shafts. They are often used in critical applications where uniform load bearing distribution requiring a long travel life and accuracy are paramount.

We therefore stock a wide range of metric and imperial diameters from 3mm to 100mm diameter, in H6 and H7 tolerances as well as offering a centreless grinding service where a non-standard diameter is required, or special tolerances are demanded by the application.

The choice of material is a crucial decision dependent on the features and functionality of the application it is being used for. At Headland we supply a wide variety of material diameters in the following:

- Induction hardened high carbon CF53 alloy steels – solid and hollow (tube) shaft

- Induction hardened stainless steels X90 & X46 – solid shaft

- Induction hardened hard chrome plated high carbon CF53 linear shafts

Click on one of the boxes on the right for more information about the material and the material data sheet to assist you with specifying your product requirements more accurately. If you need to contact us to discuss the best synergy of feature and functionality for your desired application, please don’t hesitate to call or email us.

Hardness, Straightness & Surface Finish:

All the shafts that Headland supply offer a Rockwell hardness rating of between 60-64. This gives you the confidence that our induction hardened material, with its depth of hardness, stands the test of time in the most rigorous applications. Good strength and load carrying capability, great wear resistance against deformation and fatigue, will give peace of mind that the material will retain its mechanical properties over a prolonged period.

In addition, Headland has considerable in-house experience of hardening processes, which gives our engineers the edge in having far greater flexibility in the precision and quality of their machining operations, where core hardening and annealing in smaller diameter linear shafts may be a concern.

The straightness of a Linear Shaft along its length is pivotal to its precision and success in operation. You can have confidence that the linear shaft(s) that Headland provide conform to the most stringent of straightness tolerances, between 0.1mm/m to 0.2mm/m.

Surface finish is also fundamental to a shaft’s performance in its application. Friction caused by resistance, will affect the smoothness of travel along the shaft, thereby impacting on its working life. At Headland, in addition to the excellent 8-12 CLA standard ground polished finishes that we offer, we can also offer special polishing finishes if required.

Machining:

Capabilities:

At Headland, continuous investment in state of the art CNC milling and turning machinery, as well as tremendous plant capability and capacity with our numerous centre lathes, capstan lathes, milling machines, slotting machines and hydraulic bar straightening press, ensures that we can not only just offer any engineered machining solution to your linear shaft requirements, but to any machined component that you require.

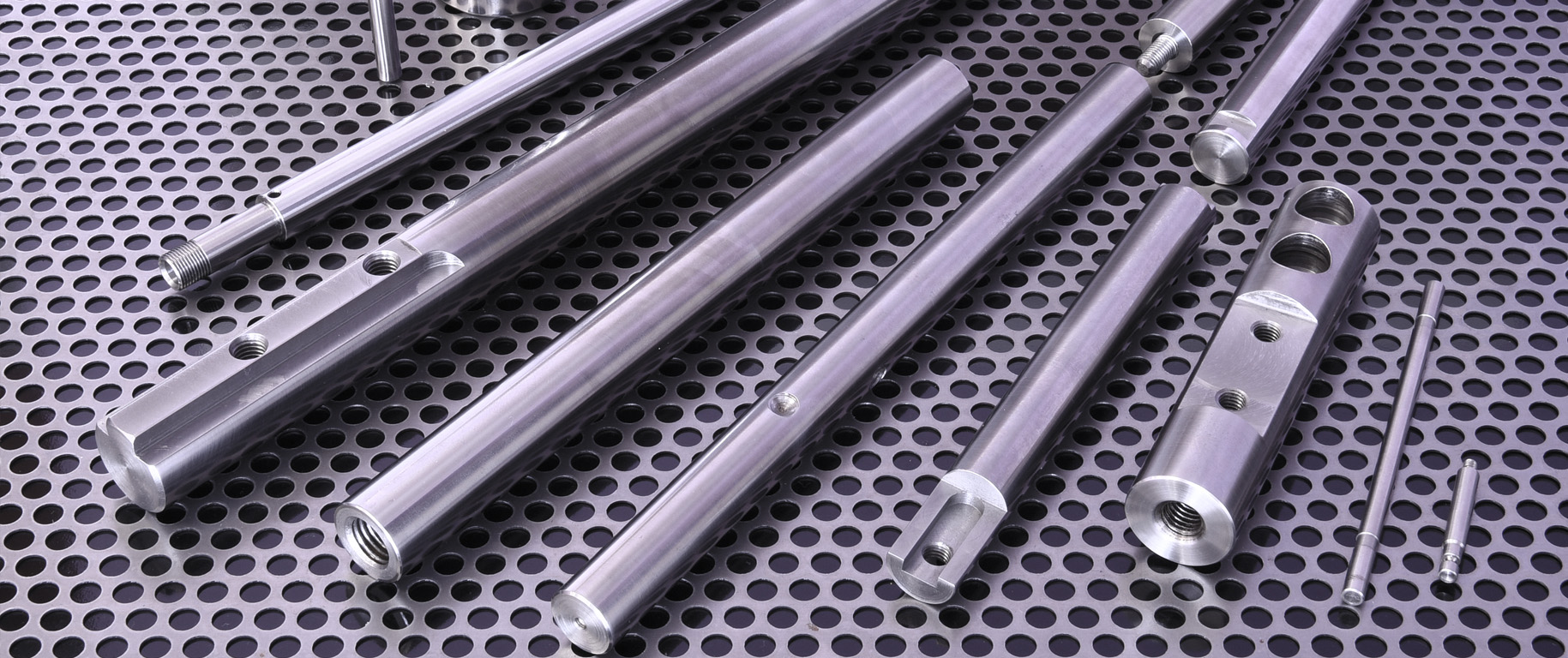

Whether you require a cut length or a linear shaft bespoke machined to drawing, a one-off prototype, or small, medium or large volume supply, Headland can cater for all your hard ground linear shaft and accessories needs.

Chamfering:

Regarding our linear shaft, whether cut lengths or machined shaft, all our products are supplied with a standard 1.5mm x 45° chamfer unless otherwise specified at the time of the order being placed or on the drawing supplied.

Bespoke Length Shafts:

Our standard shafts are stocked in 6m lengths, but longer lengths up to 7.5m can be supplied. Headland’s in-house machining capabilities ensures that any customer’s shaft length requirements can be achieved by our engineers, end machining and coupling unlimited shafts that can be supplied and joined end to end.

Don’t forget to click on our Precision Engineering page for more information on our machining capabilities!