CNC (Computer numerical control machining), is the name given to the automated manufacturing processes involved in removing material from a solid block of raw material. Essentially the process uses a block of raw metal, sometimes called the blank or workpiece and cuts the excess away resulting in a finished component. The process is known as subtractive manufacturing and is controlled by a customised computer program and executed through the use of various motorised machine tools.

At Headland our mission is to make CNC machining and manufacturing as easy as possible. From high speed machining and turning to our expert shop floor staff, our standards are high throughout and we aim to deliver you high quality precision engineered components as quickly as possible. Very often, CNC machined components are bespoke so our team will meticulously plan and manage your order throughout to achieve efficiency, quality and value, with unrivalled customer service.

What are the advantages of CNC machining?

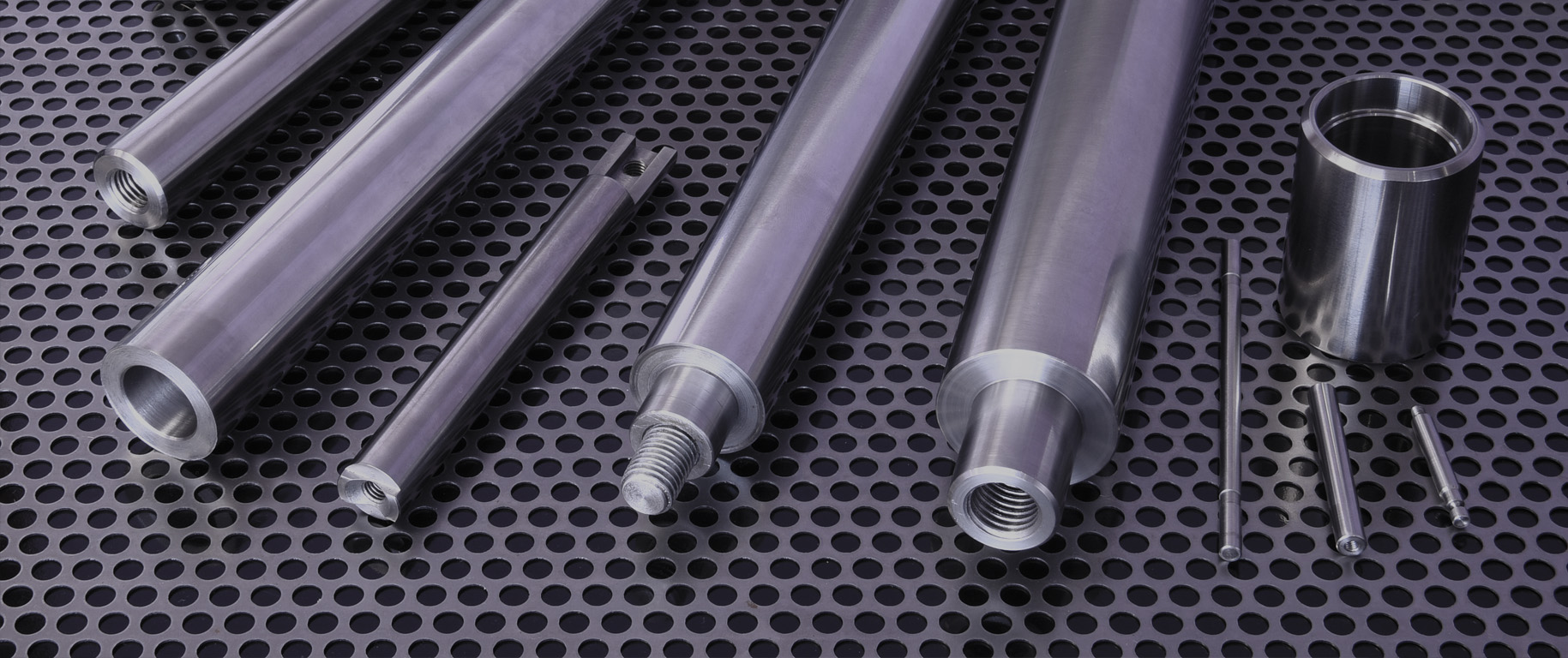

At Headland, we offer quick-turn around CNC machining that works well for rapid prototyping as well as low-volume batches of end-use components, including linear shafts. Our stock of engineering-grade metals makes CNC machining an ideal choice for functional testing. As well as this, our investment in the latest technology including XYZ CNC Proturn Centre Lathes which provide a rapid and highly efficient CNC turning service for multiple sectors throughout the UK.

Types of CNC Machines

Milling

Milling is a CNC machinery process that uses rotary cutting tools that can move along multiple axis to remove material from a block. Our CNC milling process uses 3-axis milling and 5-axis indexed milling to rapidly cut raw materials into various complex shapes and precision components.

Turning

Turning is another CNC machinery process that uses a lathe to create detailed functional prototypes and end-use components that have cylindrical features. Our turning process uses a rod stock, in a choice of metal materials. This process is used to create final parts with features including axial and radial holes, flats, grooves and slots.

CNC Machining or 3D Printing

A recent innovation in has been the rise of 3D printing technology, which builds parts from the ground up whereas CNC machining cuts away excess material to make the finished component. Though 3D printing has become more commercially viable and can be a good way of creating prototypes, it is limited to certain materials, as not every material can be adapted into filaments to use in 3D printing (in particular metals).

Industries we provide CNC Machining Services – UK

We provide CNC machining services for leading businesses in various sectors, including:

- Aerospace

- Automotive

- Oil and Gas

- Medical

- Defence

- Food and Beverage

- Railway

We can however produce precision engineered components for a variety of different sectors so speak to us to discuss your requirements today.

Why work with us?

Headland Engineering was established in 1923 and has had a long-standing reputation for providing high-quality, solid and hollow, precision hardened and ground linear steel shafts as well as linear accessories and precision engineered components. We have many years’ experience of working with leading businesses in a variety of sectors so you can rest assured you will be receiving a high-quality service, with high quality components at the end of the process.

Get in touch with the team today to discuss your requirements or to find out more about what value we can bring to your business.